- Axle sleeve thread corrector

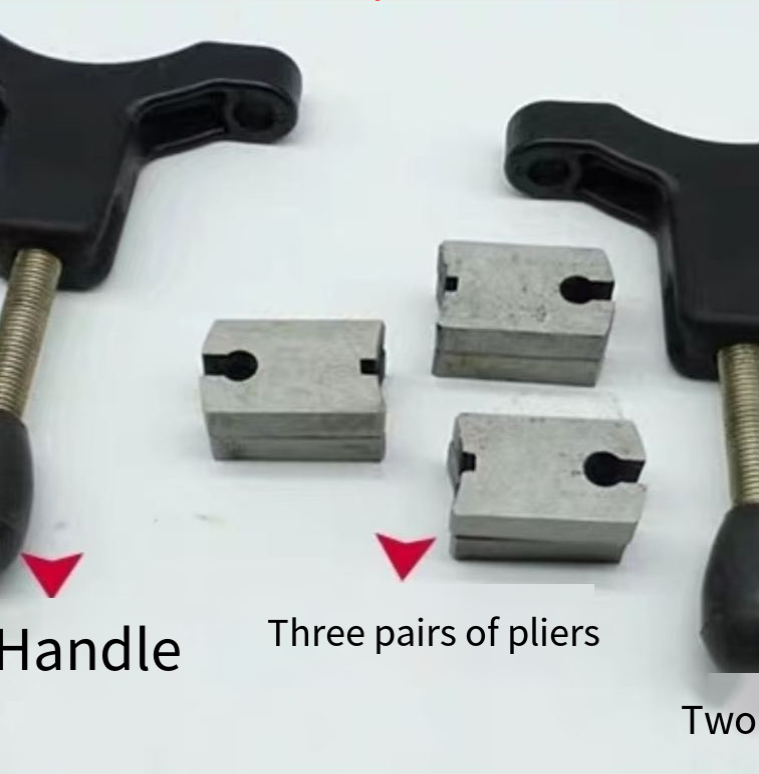

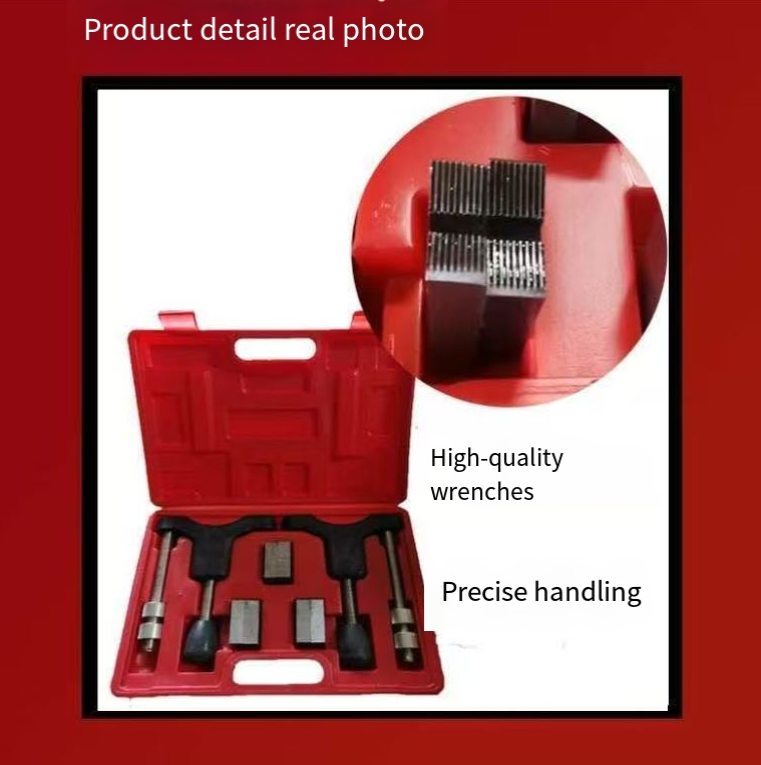

The half-shaft sleeve thread corrector is made of high-strength material and features multiple specification modules. It can precisely repair threads of different pitch. The operation is simple and does not require disassembling the entire assembly. It effectively builds a thread defense line to ensure the safety of vehicle transmission.

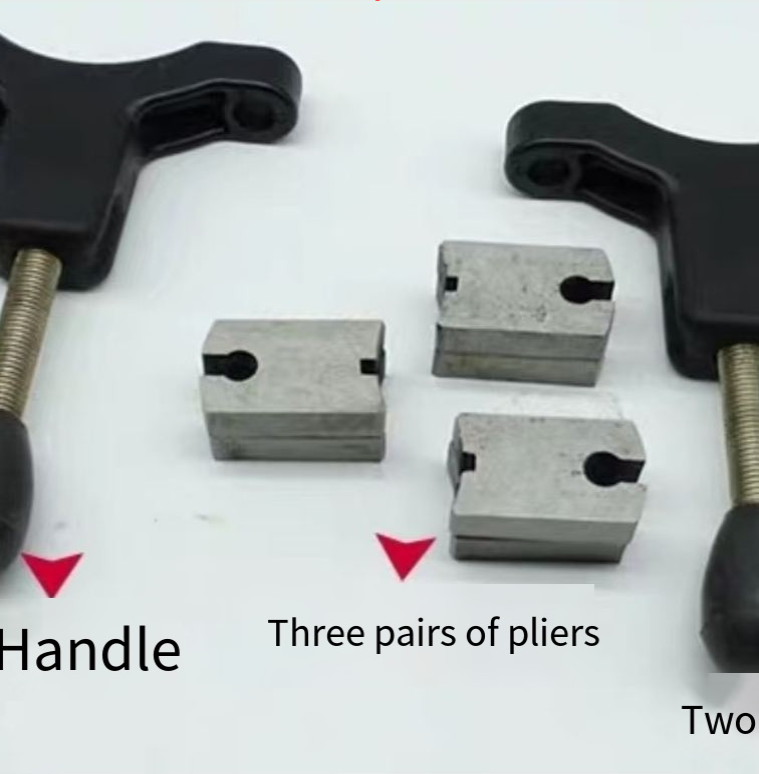

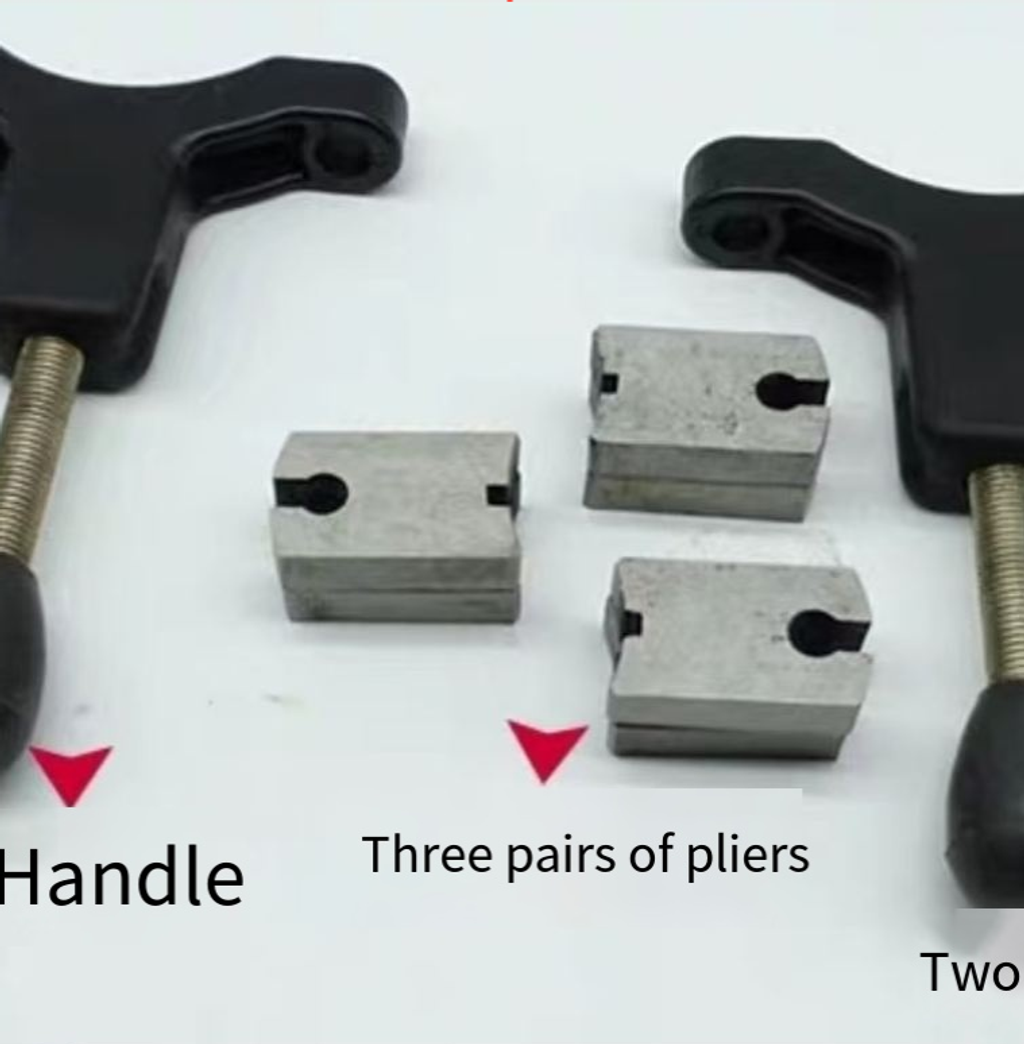

It supports a pipe diameter range of 30-110mm, and is equipped with three types of spacer blocks with pitches of 1.5mm, 1.75mm, and 2mm. It can precisely fit any semi-axle sleeve for both regular cars, heavy-duty trucks, and niche models. Auto repair shops do not need to stock multiple sets of tools; with just one set, they can handle the thread repair for multiple vehicle models. For individual car owners, if they encounter thread problems, they can also perform the repair themselves accurately, completely eliminating the awkward situation of "it can't be repaired for a specific model".

In the field of vehicle maintenance, damage to the threads of the half-shaft sleeve is often a hidden but fatal hazard. Once the threads are worn or stripped, the stability of the half-shaft will be greatly compromised, directly affecting the transmission efficiency and driving safety of the vehicle. The appearance of the half-shaft sleeve thread corrector provides efficient and precise solutions for vehicle mechanics, and can be regarded as the "thread repair expert" of the vehicle transmission system.

In the field of vehicle maintenance, damage to the threads of the half-shaft sleeve is often a hidden but fatal hazard. Once the threads are worn or stripped, the stability of the half-shaft will be greatly compromised, directly affecting the transmission efficiency and driving safety of the vehicle. The appearance of the half-shaft sleeve thread corrector provides efficient and precise solutions for vehicle mechanics, and can be regarded as the "thread repair expert" of the vehicle transmission system.

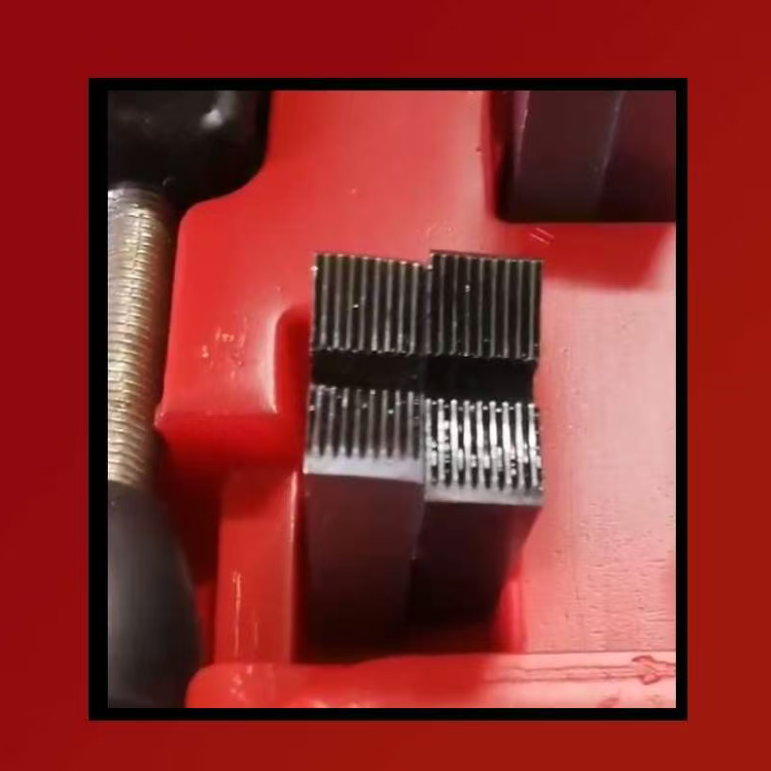

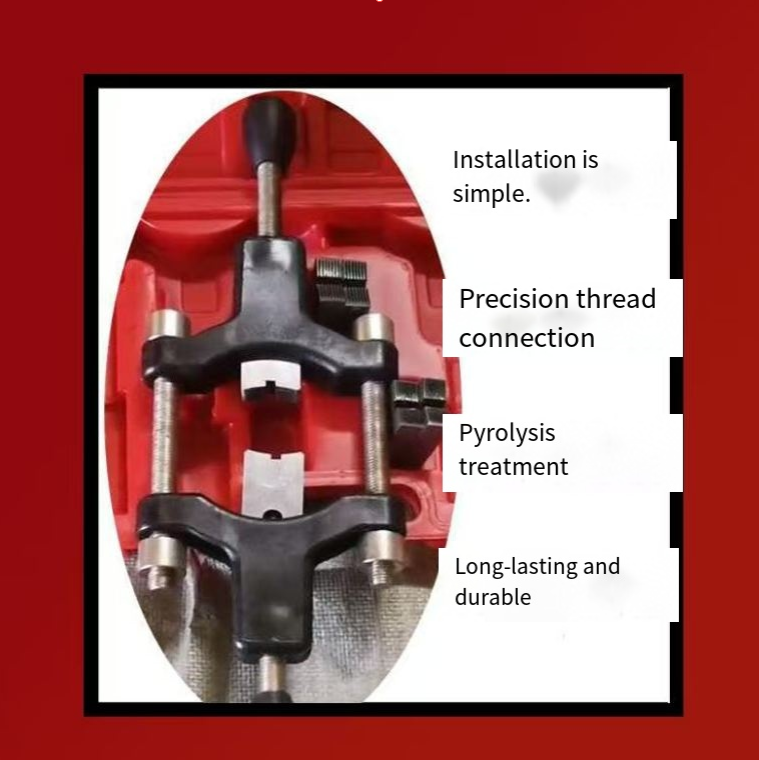

It adopts a professional mechanical structure design and is equipped with multiple specifications of thread repair modules, which can repair the threads of the half-shaft sleeve with common tooth pitches such as 1.5mm, 1.75mm, and 2mm. The tool body is made of high-strength alloy material, which is durable and sturdy. During the thread repair process, it can maintain a stable torque output and ensure that the thread repair meets the accuracy standards, comparable to the original factory process.

Its operation process is simple and convenient, even for novice mechanics, it can be quickly mastered. Just install the corresponding specification repair module onto the corrector, align with the damaged thread area, and apply uniform force by rotating the handle to gradually correct the worn part of the thread, restoring the meshing accuracy of the thread. The entire process does not require disassembling the half-shaft assembly, greatly saving maintenance time and allowing the vehicle to return to the road faster.

For vehicle repair shops, the half-shaft sleeve thread corrector is a powerful tool for improving maintenance efficiency and reducing maintenance costs. It avoids the high cost of replacing the half-shaft sleeve due to thread damage and reduces the maintenance downtime of the vehicle. For private car owners, it means that the safety of the vehicle's transmission system is guaranteed, and there is no longer need to worry about problems such as loose half-shaft or abnormal noise during driving.

From professional vehicle repair workshops to individual car maintenance, the half-shaft sleeve thread corrector, with its precise repair ability, convenient operation experience and outstanding durability, has become a benchmark tool in the field of vehicle thread repair. Choosing it means choosing the efficiency and reliability of half-shaft sleeve thread repair, and building a solid "thread defense line" for the vehicle's transmission system in every repair.

- {{p[0]}}: View image

- {{p[0]}}:

- Customization ID:{{item.custom_details?.id}}

- Preview design